![]() From alloy handling to degassing, desulfurization and decarbonizing secondary metallurgy is indispensable for the production of high-quality steel. Basic units of secondary metallurgy are vacuum degassing units (VD/VOD/VD-OB), ladle furnace (LD), RH-degassers, AOD/VODC units.

From alloy handling to degassing, desulfurization and decarbonizing secondary metallurgy is indispensable for the production of high-quality steel. Basic units of secondary metallurgy are vacuum degassing units (VD/VOD/VD-OB), ladle furnace (LD), RH-degassers, AOD/VODC units.

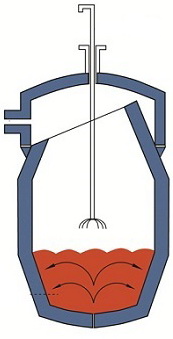

VACUUM DEGASSING UNIT

We produce magnesia-chromite products for working lining of degassers using high-quality sintered periclase and natural chromite ore with minimum content of Silica. Our products have a high resistance to erosion and ability to absorb tensions caused by thermal shock. We offer sets of refractory materials including concrete for a nozzles face side, insulation, buffer mixes, products for nozzle working lining and degasser’s chamber, ramming and hot repair mixes. Products for working lining of nozzles can be assembled prior shipment to the customers.

Selected refractory products for vacuum degassing units *

| Designation | Chemical analysis, % ** | Physical properties | |||||||

| MgO | Al2O3 | Cr2O3 | CaO | Fe2O3 | SiO2 | Density, g/cm³ | Porosity, % | Compression strength, Mpa | |

| Snorkels | |||||||||

| RI-MX01VE | 65 | 3 | 21 | 1 | 6,5 | 0,8 | ≥3,30 | ≤15 | ≥55 |

| Walls | |||||||||

| RI-MX01VMI | 63 | 5,5 | 20 | 1,2 | 9 | 0,8 | ≥3,20 | (≤13,5) | ≥55 |

| RI-MX03VMI | 55 | 5 | 24 | 1 | 8 | 0,9 | ≥3,25 | (≤13,0) | ≥55 |

STEEL LADLE

To perform working lining we apply aluminum-magnesia-carbon, periclase-aluminum-carbon and periclase-carbon products. To manufacture of these products we use high-quality fused and sintered periclase powders, fused and sintered corundum, magnesium and aluminum spinel, coarse-granulated flake graphite with low ash, synthetic resins. To give products special properties, different types of antioxidants may be added. We produce required types of products to help developing of optimal sets of linings for various conditions of steel manufacturers as well as full sets of refractory materials which include insulation and buffer mixes, products for backup and working lining, ramming and hot repair mixes, well blocks, purge blocks, mortar, gate ceramics.

To perform working lining we apply aluminum-magnesia-carbon, periclase-aluminum-carbon and periclase-carbon products. To manufacture of these products we use high-quality fused and sintered periclase powders, fused and sintered corundum, magnesium and aluminum spinel, coarse-granulated flake graphite with low ash, synthetic resins. To give products special properties, different types of antioxidants may be added. We produce required types of products to help developing of optimal sets of linings for various conditions of steel manufacturers as well as full sets of refractory materials which include insulation and buffer mixes, products for backup and working lining, ramming and hot repair mixes, well blocks, purge blocks, mortar, gate ceramics.

Selected working lining products for steel ladle *

| Designation | Chemical analysis % ** | Physical properties | ||||

| MgO | Al2O3 | C | Density g/cm³ | Porosity % | Compression strength Mpa | |

| Slag belt | ||||||

| RI-MC 01 LC | 77 | 5,5 | 14-16 | ≥3,00 | ≤4,0 | ≥40 |

| RI-MC 02 LC | 80 | 5,5 | 11-13 | ≥3,02 | ≤4,0 | ≥40 |

| Walls | ||||||

| RI-AMC 04LC | 10 | 75 | 7 | ≥3,10 | ≤8 | ≥45 |

| RI-AMC 05LC | 60 | 20 | 10 | ≥3,00 | ≤5 | ≥45 |

| RI-AMC 11LC | 10 | 70 | 7 | ≥3,15 | ≤8 | ≥50 |

| Bottom | ||||||

| RI-AMC 29LC | 20 | 60 | 10 | ≥2,98 | ≤7 | ≥45 |

| RI-AMC 31LC | 25 | 45 | 12 | ≥2,95 | ≤7 | ≥45 |

| RI-AMC 34LC | 65 | 15 | 9 | ≥2,96 | ≤7 | ≥40 |

| Impact | ||||||

| RI-AMC 01LC | 25 | 65 | 7 | ≥3,20 | ≤8 | ≥45 |

Selected ramming and buffer mixes for steel ladle *

| Designation | Chemical analysis, % | |||||

| MgO | SiO2 | Cr2O3 | Fe2O3 | P2O5 | LOI | |

| RI-BM02LC | 62 | 26 | ||||

| RI-BM04LC | 89 | 2,5 | ||||

| RI-P01LC | 91 | 2 | 0,6 | 1,8 | 3 | |

| RI-P02LC | 92 | - | 0,9 | 2,36-3,6 | ||

Selected wet/dry gunning and ramming mixes for tundish *

| Designation | Chemical analysis, % | |||

| SiO2 | Fe2O3 | MgO | ||

| RI-G01TC | 25 | 5,5 | 65 | |

| RI-G04TC | 28,5 | 7 | 57,5 | |

| RI-DV02TC | 27 | - | 60 | |

| RI-DV03TC | 12,5 | - | 80 | |

| RI-DV04TC | 6,5 | - | 83,5 | |

* – The values are typical and derived from existing standards. Not a specification.

** – The figures are exclusive of the ignition losses.